Product List

-

“VEGA” Porous Vitrified Bond Wheel for Wafers Finishing Grinding

Higher surface roughness realized by intermediate processing and final processing of SiC and GaN wafers

Higher surface roughness realized by intermediate processing and final processing of SiC and GaN wafers

■Higher surface roughness is realized by the combination of ultra-fine diamond abrasive grains and vitrified bonds of large and fine porous combination structure.

■Spontaneous blade generation is realized and cutting quality is maintained by bonds that can make ultrafine shredding.

■Stable high-quality surface and low processing cost can be realized. -

“Taffair” Porous Metal Bond Wheel for Compound Semiconductor Wafers

High grinding performance and long tool life for processing of sapphire or SiC wafers

High grinding performance and long tool life for processing of sapphire or SiC wafers

■The porous structure of metal bonds improves biting for higher grinding performance and enhances heat dissipation for longer tool life.

■Not only abrasion resistance of highly rigid metal bonds but also maintaining of cutting quality by appropriate spontaneous blade generation are realized.

■Longer tool life contributes to the stabilization of processing quality and reduction of processing cost. -

“Metarex” diamond wheels for high-efficient grinding of difficult-to-cut materials

These metal bond wheels are designed with a new concept, and have both the high cutting performance of resin bonds and the abrasion resistance of metal bonds. They are suitable for efficient grinding of difficult-to-cut materials such as Al2O3-TiC and quartz.

These metal bond wheels are designed with a new concept, and have both the high cutting performance of resin bonds and the abrasion resistance of metal bonds. They are suitable for efficient grinding of difficult-to-cut materials such as Al2O3-TiC and quartz. -

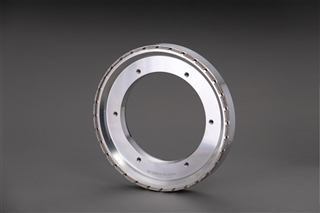

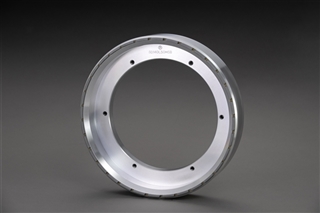

Diamond wheels for edge grinding (beveling) semiconductor wafers

This wheel is used for edge grinding (beveling) semiconductor wafers.

This wheel is used for edge grinding (beveling) semiconductor wafers.

We offer "ME" bond for wheels for chamfering silicon wafers with excellent sharpness and high maintenance of groove shape. The finished surface roughness is excellent, and the amount of polishing after chamfering is reduced, leading to lower total processing costs by reducing the post-process time and consumables.

For wheels for chamfering SiC and sapphire wafers, we offer bond wheels with excellent sharpness and grinding durability. Electrodeposition bond chamfering wheels are also available for small and medium volume production.

For wheels for chamfering LT and LN wafers, we offer bond specifications that suppress the occurrence of chipping on brittle wafers.

In addition to general R-shaped (round/full round) and T-shaped grooves, special shapes such as asymmetrical shapes are also covered, so please consult with us.

[Applicable materials for diamond beveling wheels]

Silicon, SiC (silicon carbide), Sapphire, LT (lithium tantalate), LN (lithium niobate), GaN (gallium nitride), GaAs (gallium arsenide), and Quartz -

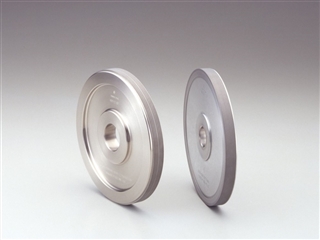

Diamond notch wheel for semiconductor wafers

This wheel is used for chamfering and finishing the notch of semiconductor wafers. The runout accuracy of the diamond layer to the shank is excellent due to our original processing technology. In addition to silicon wafers, we also provide wheels with various specifications for compound semiconductor wafers such as SiC (silicon carbide) and LT (lithium tantalate), which are becoming larger nowadays, and for quartz wafers.

This wheel is used for chamfering and finishing the notch of semiconductor wafers. The runout accuracy of the diamond layer to the shank is excellent due to our original processing technology. In addition to silicon wafers, we also provide wheels with various specifications for compound semiconductor wafers such as SiC (silicon carbide) and LT (lithium tantalate), which are becoming larger nowadays, and for quartz wafers.

[Applicable materials for diamond notch wheels]

Silicon, SiC (silicon carbide), LT (lithium tantalate), LN (lithium niobate), Quartz, and Sapphire -

Diamond multi-layer wheels

A single wheel of this type can perform multiple grinding processes such as rough grinding, pre-finishing, and finishing. This allows multiple processes to be performed with a single machine without replacing tools, which reduces processing time. Multi-layer wheels with a combination of metal bonds for rough grinding, resin bonds for pre-finishing, and resin bonds for finishing are available.

A single wheel of this type can perform multiple grinding processes such as rough grinding, pre-finishing, and finishing. This allows multiple processes to be performed with a single machine without replacing tools, which reduces processing time. Multi-layer wheels with a combination of metal bonds for rough grinding, resin bonds for pre-finishing, and resin bonds for finishing are available. -

Diamond wheels for mirror finishing of difficult-to-cut materials

"BL" porous resin bond wheels are designed for mirror grinding of cemented carbide / tungsten carbide molds, ceramics, silicon wafers, and hardening steel alloys. With the effect of pores and a heat-resistant bond strengthened by special filler, these wheels produce high quality finished surfaces while maintaining their cutting performance.

"BL" porous resin bond wheels are designed for mirror grinding of cemented carbide / tungsten carbide molds, ceramics, silicon wafers, and hardening steel alloys. With the effect of pores and a heat-resistant bond strengthened by special filler, these wheels produce high quality finished surfaces while maintaining their cutting performance. -

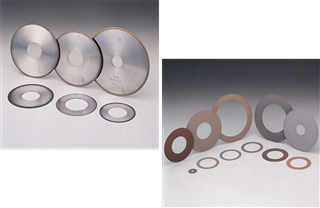

Diamond blade for package board cutting

Precision blade for cutting package boards.

Precision blade for cutting package boards.

We offer a rim saw type blade with a metal base (base metal) and an all-blade type.

Metal bond blade with good sharpness and cutting quality.

Stable sharpness without deterioration due to copper adhesion prevents cracking and chipping of package boards.

Depending on the blade thickness and particle size, the V-face shape of the cutting edge has the effect of suppressing the occurrence of initial chipping of the board.

We can also offer a dress board for dressing blades and propose the most appropriate dress board for the blade specifications.

It is widely used for machining of not only package boards, but also laminated ceramics, magnetic materials, and optical glasses.