Longer life of edge grinding (beveling) wheels for compound semiconductor wafers

[Issues in beveling compound semiconductor wafers]

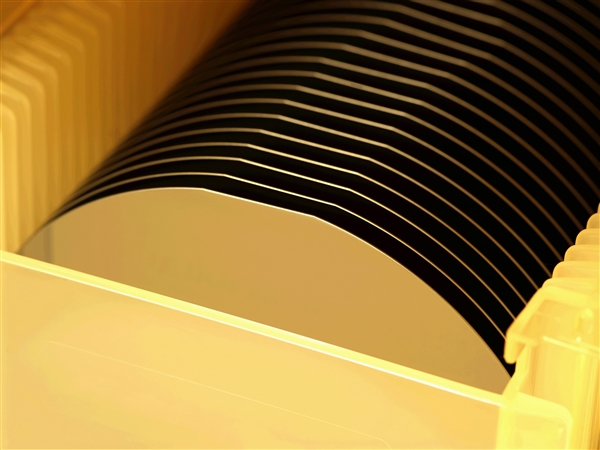

The production of compound semiconductor wafers, which are used as substrates for power devices, is expected to grow steadily in the trend toward power saving in a low-carbon society. The key to this growth is the machining cost of wafers, and it is important to improve the life of diamond tools in the edge grinding (beveling) process. It is necessary to reduce chipping and extend the wheel life.[Solution with metal bond beveling wheel]

A longer wheel life leads to benefits such as shorter cycle time with less replacement of tools and lower total cost of use. Our metal bond edge grinding (beveling) wheels are optimized for SiC (Silicon Carbide) and GaN (Gallium Nitride) wafer machining to reduce chipping and achieve long tool life.We also offer electroplated edge grinding (beveling) wheels with excellent sharpness and cost performance.

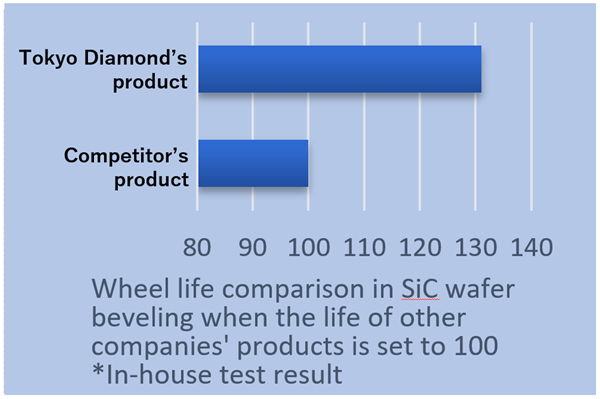

Comparison of beveling wheel life for SiC wafers

Life improved by more than 30% compared to wheels made by other companies

By improving the geometric accuracy of the wheel and developing a metal bond optimized for compound semiconductor wafers, we were able to obtain the test result that the wheel life in the SiC wafer edge grinding (beveling) process increased by more than 30% compared to other manufacturers' products.

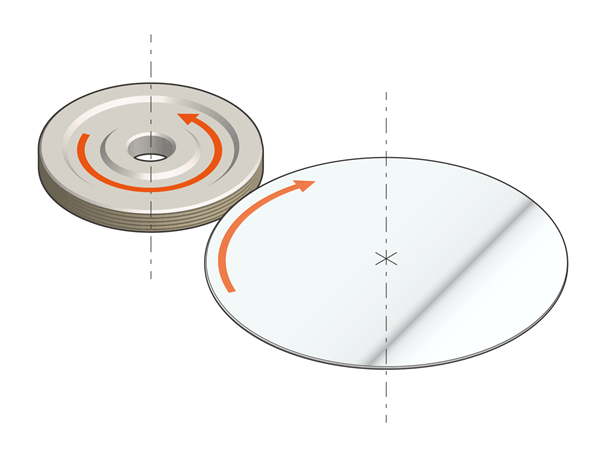

Optimal grinding tools for beveling semiconductor wafers

Metal bond wheel for compound semiconductor wafers

[Possible production range]

Grain size : #400 - #3000 *Compound grain size is also available.

Outer diameter : Up to 202D

Internal diameter tolerance: H6

(Please consult with us for other tolerances.)

Dynamic balance: ≧0.1 g @Min.

Groove shape tolerance : ≧ 0.5 degrees

Number of grooves: Up to 10 grooves (more than 10 grooves are possible

depending on groove shape.)

Diamond with unique abrasive grain control is used to reduce the incidence of chipping and the machining damage.

The use of a bond with excellent abrasion resistance ensures high dimensional stability of the wheel shape and long life.