Realization of highly efficient machining of difficult-to-cut materials such as alumina and Si3N4

[Issues in grinding difficult-to-cut materials]

Alumina and silicon nitride are representative materials of fine ceramics and are widely used in industrial machine parts due to their high hardness and excellent wear resistance. There is a need for tools that can grind these hard and difficult-to-cut materials with high efficiency in a short time while maintaining their cutting performance.[Solution with metal bond wheel]

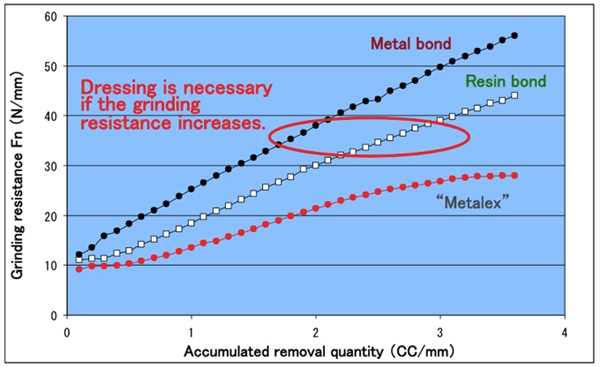

Compared to resin bond wheels, metal bond wheels have a higher abrasive grain retention and a longer service life. However, when grinding difficult-to-cut materials, the grinding capacity of conventional bond wheels is insufficient due to abrasive grain wear and shedding. Our Metarex wheels have an excellent self-dressing effect because the special bonding agent falls off at the same time as the abrasive grains fall off, resulting in durable grindability and efficient processing.

In addition to ceramics, this wheel is effective for high-efficiency machining of crystal, quartz, cemented carbide, etc.

Comparison of grinding resistance with resin bond and metal bond

Test Conditions for Grinding Resistance Comparison

Machine : Horizontal spindle surface grinder

Material : Si3N4 (silicon nitride )

Wheel size : 200Dx8T (1A1)

Optimal grinding tools for highly efficient grinding of difficult-to-cut materials

Metarex” Metal bond wheels for high-efficient grinding of difficult-to-cut materials

These metal bond wheels are designed with a new concept, and have both the high cutting performance of resin bonds and the abrasion resistance of metal bonds. They are suitable for efficient grinding of difficult-to-cut materials such as Al2O3-TiC and quartz.