Diamond wheels for edge grinding (beveling) semiconductor wafers

This wheel is used for edge grinding (beveling) semiconductor wafers.

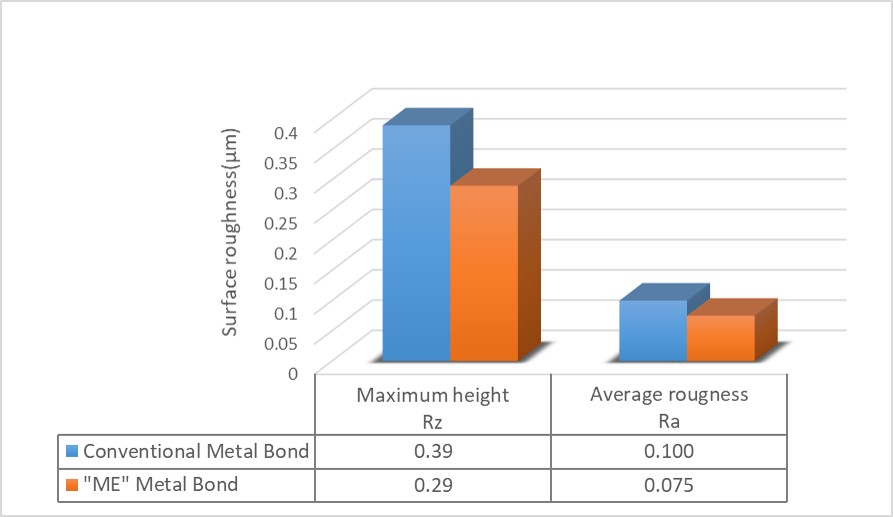

We offer "ME" bond for wheels for chamfering silicon wafers with excellent sharpness and high maintenance of groove shape. The finished surface roughness is excellent, and the amount of polishing after chamfering is reduced, leading to lower total processing costs by reducing the post-process time and consumables.

For wheels for chamfering SiC and sapphire wafers, we offer bond wheels with excellent sharpness and grinding durability. Electrodeposition bond chamfering wheels are also available for small and medium volume production.

For wheels for chamfering LT and LN wafers, we offer bond specifications that suppress the occurrence of chipping on brittle wafers.

In addition to general R-shaped (round/full round) and T-shaped grooves, special shapes such as asymmetrical shapes are also covered, so please consult with us.

We offer "ME" bond for wheels for chamfering silicon wafers with excellent sharpness and high maintenance of groove shape. The finished surface roughness is excellent, and the amount of polishing after chamfering is reduced, leading to lower total processing costs by reducing the post-process time and consumables.

For wheels for chamfering SiC and sapphire wafers, we offer bond wheels with excellent sharpness and grinding durability. Electrodeposition bond chamfering wheels are also available for small and medium volume production.

For wheels for chamfering LT and LN wafers, we offer bond specifications that suppress the occurrence of chipping on brittle wafers.

In addition to general R-shaped (round/full round) and T-shaped grooves, special shapes such as asymmetrical shapes are also covered, so please consult with us.

[Applicable materials for diamond beveling wheels]

Silicon, SiC (silicon carbide), Sapphire, LT (lithium tantalate), LN (lithium niobate), GaN (gallium nitride), GaAs (gallium arsenide), and Quartz

Surface roughness comparison of grinding test of silicon wafer(after 120 pcs)

Reference sizes and specifications for diamond beveling wheels

■Grain size : #400 - #3000

*It is possible to manufacture wheels usable for both roughing and finishing

■Outer diameter: φ102, φ202

(Please contact us for other sizes.)

■Internal diameter tolerance: H6

(Please consult with us for other tolerances.)

■Dynamic balance: ≥ 0.1 g @Min.

■Groove angle tolerance: Tolerance ≥ 0.5 degrees (one side angle)

Bond for beveling wheels

Metal bond

- Industories

- Work materials

- Processing methods