Product List

-

“Metarex” diamond wheels for high-efficient grinding of difficult-to-cut materials

These metal bond wheels are designed with a new concept, and have both the high cutting performance of resin bonds and the abrasion resistance of metal bonds. They are suitable for efficient grinding of difficult-to-cut materials such as Al2O3-TiC and quartz.

These metal bond wheels are designed with a new concept, and have both the high cutting performance of resin bonds and the abrasion resistance of metal bonds. They are suitable for efficient grinding of difficult-to-cut materials such as Al2O3-TiC and quartz. -

Metal bond mounted wheels for machining of hard and brittle materials

Diamond metal bond wheels with spindle are specially designed for machining hard and brittle materials.

Diamond metal bond wheels with spindle are specially designed for machining hard and brittle materials.

We offer the most suitable bond specifications for various materials in the grinding process of hard and brittle materials using a machining/gliding center.

The metal bond wheel has high abrasive grain retention and high sharpness even when machining hard materials. It also has good thermal conductivity, which prevents heat buildup at the machining point and prevents thermal cracking of brittle materials. The tool life is longer than that of electrodeposition tools with a single diamond layer, and it is the best tool for machining ceramics, especially hard SiC and aluminum nitride.

In the machining of quartz glass, the optimum bond selection ensures high grinding durability. -

Diamond / CBN wheels for grinding with formed tools

This wheels is used for forming / grooving of fine ceramics, quartz and other hard brittle materials and high-speed steel, and chamfering of glass substrates.

This wheels is used for forming / grooving of fine ceramics, quartz and other hard brittle materials and high-speed steel, and chamfering of glass substrates.

The "MB" bond series is a resin bond wheel with high shape retention using heat-resistant resin and metal filler. It has high sharpness and high shape retention in heavy-duty grinding with a large depth of cut.

The ability to form by electrical discharge machining makes it possible to form differently shaped abrasive grain layers, which are usually difficult to form, making this bond very suitable for machining with formed tools in plunge grinding.

The "MB" bond series is a bond that works well with both diamond and CBN wheels.

The diamond wheels are suitable for machining with formed tools for quartz, ceramics, and cemented carbides.

CBN wheels are suitable for the machining of high-speed steel blades and for machining with formed tools for iron-based machine parts that require high accuracy.

Since the wheels are heat resistant and capable of heavy-duty grinding, we have experience in machining with formed tools using multi-wheels that combine several wheels. -

Diamond wheels for mirror finishing of difficult-to-cut materials

"BL" porous resin bond wheels are designed for mirror grinding of cemented carbide / tungsten carbide molds, ceramics, silicon wafers, and hardening steel alloys. With the effect of pores and a heat-resistant bond strengthened by special filler, these wheels produce high quality finished surfaces while maintaining their cutting performance.

"BL" porous resin bond wheels are designed for mirror grinding of cemented carbide / tungsten carbide molds, ceramics, silicon wafers, and hardening steel alloys. With the effect of pores and a heat-resistant bond strengthened by special filler, these wheels produce high quality finished surfaces while maintaining their cutting performance. -

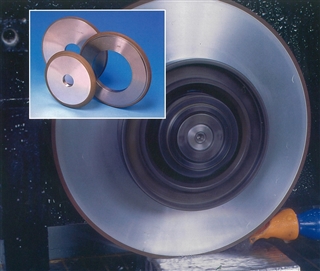

Large Size Resin Bond Wheel

■ Single-piece formation of a resin bond wheel with a maximum outer diameter of φ600mm and width of T100mm can be realized.

■ Single-piece formation of a resin bond wheel with a maximum outer diameter of φ600mm and width of T100mm can be realized.

■ Grinding trace at joint is eliminated.

■ Dynamic balance of 0.1μm is realized for products with a dedicated flange. -

“DEX” diamond wheels for forming difficult-to-cut materials

These wheels are designed for high shape precision forming of, for example, motor cores. Wheels of the most appropriate specifications are available for not only magnetic materials such as neodymium-iron, but also for ferrites, ceramics and glass.

These wheels are designed for high shape precision forming of, for example, motor cores. Wheels of the most appropriate specifications are available for not only magnetic materials such as neodymium-iron, but also for ferrites, ceramics and glass. -

“DEX” diamond wheel for optical lens centering

This wheel is used for axis alignment (optical lens centering) of aspherical lenses or steppers used in high-grade cameras or endoscopes, which usually require high-precision grinding. When used, pre-conditioning grinding is not necessary and lens manufacturing with less damage on the lens edge starts from the beginning of processing work. The wheel can also suppress lens coloring, even when a steep rise shape is used.

This wheel is used for axis alignment (optical lens centering) of aspherical lenses or steppers used in high-grade cameras or endoscopes, which usually require high-precision grinding. When used, pre-conditioning grinding is not necessary and lens manufacturing with less damage on the lens edge starts from the beginning of processing work. The wheel can also suppress lens coloring, even when a steep rise shape is used. -

“Metalist” CBN Metal Bond Wheel for Iron Material

By using the metal bond having significantly higher heat conduction than a vitrified bond, the influence of heat on the working surface is minimized.

By using the metal bond having significantly higher heat conduction than a vitrified bond, the influence of heat on the working surface is minimized.

■ The product not only maintains cutting performance and realizes long tool life, but also suppresses burning of work materials.

■ Since it can suppress heat stress on work materials more than conventional abrasive wheels, reduction of the fatigue-resistant strength of the work can be suppressed.

■ Little damage on abrasive grains and appropriate spontaneous blade generation can realize long dress intervals and reduce down time.

[Target materials for CBN metal bond wheels]

- HSS (High-Speed Steel)

- Hardened Steel (carbon steel, die steel) -

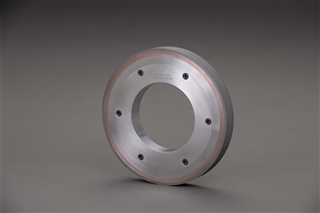

CBN wheels for grinding iron materials

These wheels realize high-precision grinding of iron materials used for automobile parts and the like. They provide the advantages of high performance and stable quality. CBN wheels with an axis are also available.

These wheels realize high-precision grinding of iron materials used for automobile parts and the like. They provide the advantages of high performance and stable quality. CBN wheels with an axis are also available. -

“CITIUS” diamond wheels for heavy grinding of carbide tools

These wheels demonstrate their distinguished performance for deep-gutter flute grinding of cemented carbide / tungsten carbide tools. Compared to conventional resin bond wheels, they reduce machining time and abrasion. They also achieve stable cutting performance, high-precision, and high-quality surface roughness, and reduce the generation of chips. "BI30" and "MB" series resin bond wheels are also available depending on the materials to be ground and on usage.

These wheels demonstrate their distinguished performance for deep-gutter flute grinding of cemented carbide / tungsten carbide tools. Compared to conventional resin bond wheels, they reduce machining time and abrasion. They also achieve stable cutting performance, high-precision, and high-quality surface roughness, and reduce the generation of chips. "BI30" and "MB" series resin bond wheels are also available depending on the materials to be ground and on usage.