Diamond / CBN wheels for grinding with formed tools

This wheels is used for forming / grooving of fine ceramics, quartz and other hard brittle materials and high-speed steel, and chamfering of glass substrates.

The "MB" bond series is a resin bond wheel with high shape retention using heat-resistant resin and metal filler. It has high sharpness and high shape retention in heavy-duty grinding with a large depth of cut.

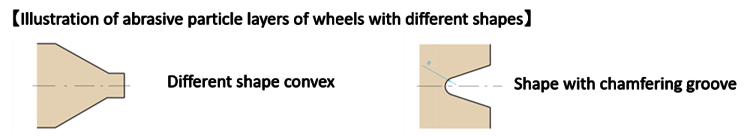

The ability to form by electrical discharge machining makes it possible to form differently shaped abrasive grain layers, which are usually difficult to form, making this bond very suitable for machining with formed tools in plunge grinding.

The "MB" bond series is a bond that works well with both diamond and CBN wheels.

The diamond wheels are suitable for machining with formed tools for quartz, ceramics, and cemented carbides.

CBN wheels are suitable for the machining of high-speed steel blades and for machining with formed tools for iron-based machine parts that require high accuracy.

Since the wheels are heat resistant and capable of heavy-duty grinding, we have experience in machining with formed tools using multi-wheels that combine several wheels.

The "MB" bond series is a resin bond wheel with high shape retention using heat-resistant resin and metal filler. It has high sharpness and high shape retention in heavy-duty grinding with a large depth of cut.

The ability to form by electrical discharge machining makes it possible to form differently shaped abrasive grain layers, which are usually difficult to form, making this bond very suitable for machining with formed tools in plunge grinding.

The "MB" bond series is a bond that works well with both diamond and CBN wheels.

The diamond wheels are suitable for machining with formed tools for quartz, ceramics, and cemented carbides.

CBN wheels are suitable for the machining of high-speed steel blades and for machining with formed tools for iron-based machine parts that require high accuracy.

Since the wheels are heat resistant and capable of heavy-duty grinding, we have experience in machining with formed tools using multi-wheels that combine several wheels.

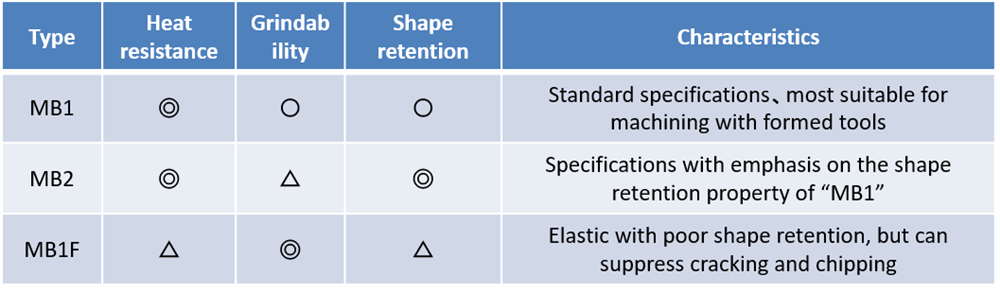

MB Bond Lineup

Major characteristics

■Resin bond wheel suitable for heavy-duty grinding of high-strength/high hardness workpieces

■Resin bond wheel with high shape retention, like metal bond wheels

■Capable of forming by electrical discharge machining, enabling different shapes that are usually difficult to achieve with resin bonds.

Bond for grinding wheels

Resin bond

- Industories

- Work materials

- Processing methods