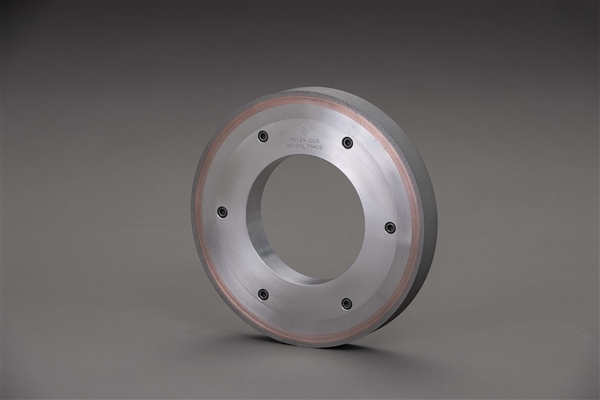

“Metalist” CBN Metal Bond Wheel for Iron Material

By using the metal bond having significantly higher heat conduction than a vitrified bond, the influence of heat on the working surface is minimized.

■ The product not only maintains cutting performance and realizes long tool life, but also suppresses burning of work materials.

■ Since it can suppress heat stress on work materials more than conventional abrasive wheels, reduction of the fatigue-resistant strength of the work can be suppressed.

■ Little damage on abrasive grains and appropriate spontaneous blade generation can realize long dress intervals and reduce down time.

- Hardened Steel (carbon steel, die steel)

■ The product not only maintains cutting performance and realizes long tool life, but also suppresses burning of work materials.

■ Since it can suppress heat stress on work materials more than conventional abrasive wheels, reduction of the fatigue-resistant strength of the work can be suppressed.

■ Little damage on abrasive grains and appropriate spontaneous blade generation can realize long dress intervals and reduce down time.

[Target materials for CBN metal bond wheels]

- HSS (High-Speed Steel)- Hardened Steel (carbon steel, die steel)

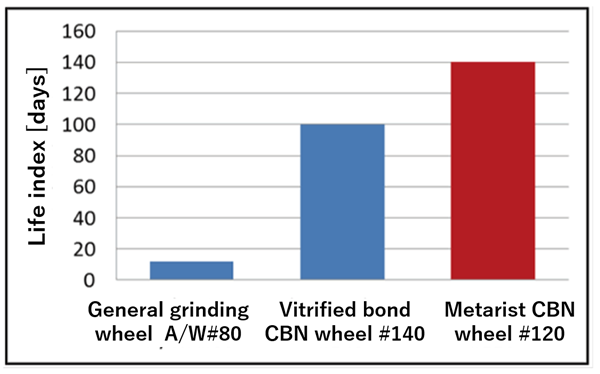

Comparison of life index with general grinding wheel/vitrified CBN wheel

Test conditions for life index comparison

- Machine : Centerless grinding machine

Grinding method : Through-feed grinding - Work material : SCM carbon steel (JIS) hardnes (HRC47)

- Work size : (φ6-3.5L)-2.8d-38L

Wheel size : φ300-42T(3X)

Bond for grinding wheels

Metal bond

- Industories

- Work materials

- Processing methods