Metal bond mounted wheels for machining of hard and brittle materials

Diamond metal bond wheels with spindle are specially designed for machining hard and brittle materials.

We offer the most suitable bond specifications for various materials in the grinding process of hard and brittle materials using a machining/gliding center.

The metal bond wheel has high abrasive grain retention and high sharpness even when machining hard materials. It also has good thermal conductivity, which prevents heat buildup at the machining point and prevents thermal cracking of brittle materials. The tool life is longer than that of electrodeposition tools with a single diamond layer, and it is the best tool for machining ceramics, especially hard SiC and aluminum nitride.

In the machining of quartz glass, the optimum bond selection ensures high grinding durability.

We offer the most suitable bond specifications for various materials in the grinding process of hard and brittle materials using a machining/gliding center.

The metal bond wheel has high abrasive grain retention and high sharpness even when machining hard materials. It also has good thermal conductivity, which prevents heat buildup at the machining point and prevents thermal cracking of brittle materials. The tool life is longer than that of electrodeposition tools with a single diamond layer, and it is the best tool for machining ceramics, especially hard SiC and aluminum nitride.

In the machining of quartz glass, the optimum bond selection ensures high grinding durability.

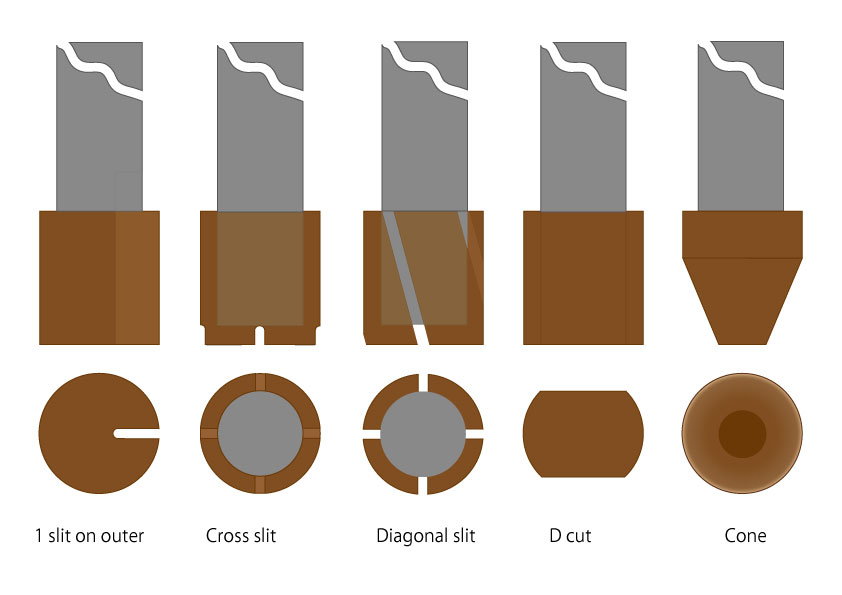

Shape example of metal bonded mounted wheel

Applicable Materials for Metal Bonded Mounted Wheels

We can propose the most suitable bond specifications according to the processing material.

We can propose various shape variations to suit your application.

Even for small-diameter wheels, in which maintaining a core drill shape is difficult, we can offer shapes with slits to improve chip evacuation.

[ Applicable materials ]

Slicon carbide (SiC), alumium nitride (AlN), silicon nitride (Si3N4),

quartz glass,alumina ceramics (Al2O3), silicon, and sapphire

Bond for Mounted Wheels

Metal bond

- Industories

- Work materials

- Processing methods