Product List

-

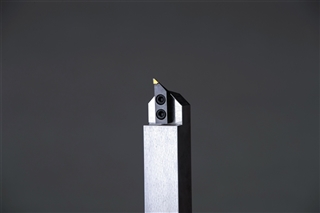

“Arcceed” mono-crystal diamond cutting toolThis is a mono-crystal diamond radius cutting tool with a cutting edge waviness of 50 nm or less. It realizes high-precision machining, thus reducing mold production processing requirements. Due to its fine rake and clearance surface, it can elicit better performance of a 3-axis machining device and improve the copying performance of molds. It also realizes high-precision machining by a 2-axis machining device.

[Typical applications of highly contoured mono-crystal diamond cutting tools]

Camera lens molds for smartphones, PC and tablets, pickup lens molds, ultra-precision machining, infrared lenses, various spherical and aspherical lenses. -

“Arcceed” mono-crystal diamond end mill

This high quality mono-crystal diamond ball end mill can be used at speeds up to 100,000 revolutions per minute (RPM). It has a fine cutting edge and a low axis deviation. W.A.90 products will be available.

This high quality mono-crystal diamond ball end mill can be used at speeds up to 100,000 revolutions per minute (RPM). It has a fine cutting edge and a low axis deviation. W.A.90 products will be available. -

Mono-crystal diamond ultrafine cutting tool

These mono-crystal diamond bites have fine cutting edges made of single-crystal diamonds, which have excellent wear resistance and can make the edges very sharp. By using single-crystal diamond microbites, a cutting edge controlled in micrometers (μm) is transferred to a workpiece, and a fine groove pattern can be formed with high precision and a continuous pitch.

These mono-crystal diamond bites have fine cutting edges made of single-crystal diamonds, which have excellent wear resistance and can make the edges very sharp. By using single-crystal diamond microbites, a cutting edge controlled in micrometers (μm) is transferred to a workpiece, and a fine groove pattern can be formed with high precision and a continuous pitch.

[Typical applications of mono-crystal diamond ultrafine cutting tool]

Machining of optical films for FPDs and precision molds for optical elements Micro-pattern forming and planer machining Machining of diffraction gratings Other MEMS and bio-related micro-pattern machining -

Mono-crystal diamond cutting tools / MCD bitesWe have over 80 years of experience in manufacturing single-crystal diamond bites for cutting processes and have supplied tools for precision machining applications periodically.

By grinding Mono Crystal Diamond (MCD), the hardest material on earth, to a sharp cutting edge, mirror-finish machining is possible in cutting that cannot be obtained with ordinary cemented carbide or PCD (polycrystalline diamond) bites.

The extremely sharp cutting edge can be applied to soft and viscous gold and copper alloys that would be scuffed or crushed by ordinary cutting bites, and a good cutting surface can be obtained.

When cutting acrylic resin, a transparent cutting surface can be obtained without the need for polishing.

We custom-design the optimum specifications to meet your machining requirements and tool geometry. Various insert tip types are also available.