Case studies on wafer processing with diamond wheels in the semiconductor industry

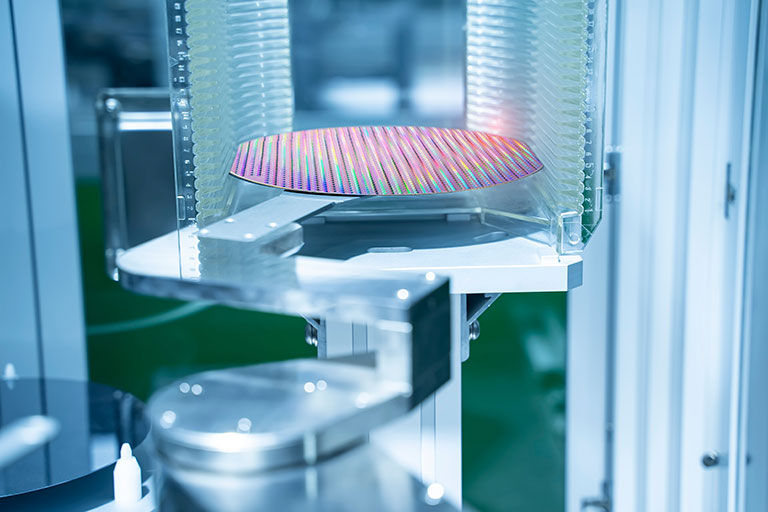

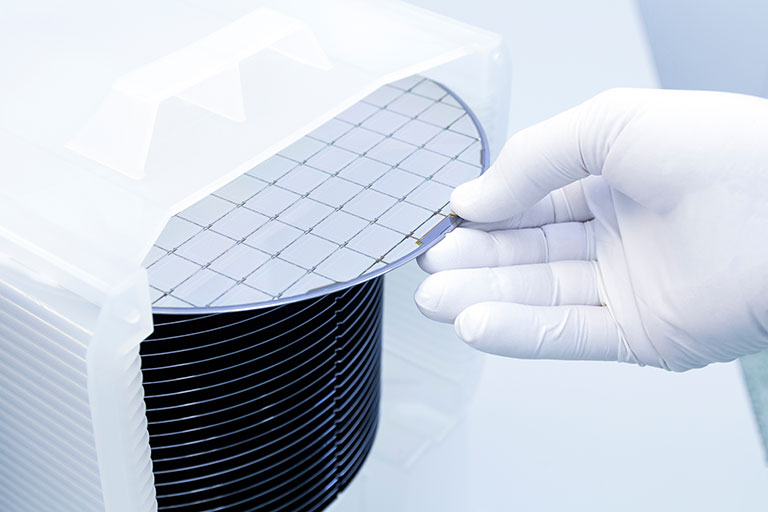

Diamond wheels are grinding wheels with cutting edges made of diamond grains. While these wheels find applications across different industries, there has been a significant increase in the demand for machining semiconductor wafers in recent years due to the advanced processes in semiconductor manufacturing.

This article compiles case studies highlighting problem-solving examples in “wafer processing "using diamond wheels.

Challenges in wafer processing in the semiconductor industry

In the semiconductor industry, manufacturing processes are becoming increasingly sophisticated, such as high miniaturization of semiconductors and 3D stacking. The rapid expansion of the EV (electric vehicle) market has resulted in an increasing number of more energy efficient SiC wafers for power semiconductors.

SiC wafers and silicon wafers used in semiconductors are also known as hard, brittle, difficult-to-machine materials, posing a challenge in terms of efficient manufacturing. This is where diamond wheels come into play.

What is a power semiconductor?

Power semiconductors are devices that convert several types of power through switching operations. As the term "switching" implies, the power semiconductors convert direct current into alternating current (inverter) and alternating current into direct current (converter) by repeatedly turning switches ON/OFF at high speed. Additionally, power semiconductors can change frequencies and convert voltages (regulator).

References: AIST Magazine|National Institute of Advanced Industrial Science and Technology

Diamond is the hardest material on Earth, making it ideal for processing hard and brittle materials, which are difficult to machine with conventional abrasive grains.

Compared to general grinding wheels, diamond wheels have a longer tool life and can be used under high-efficiency machining conditions. As an indispensable tool for wafer processing, diamond wheels address various challenges in the field.

- Related article| Useful basic knowledge of diamond wheels

Problem-solving examples in wafer processing using diamond wheels

The Tokyo Diamond Tools Mfg. offers a lineup of various diamond tools for wafers processing.

Here are some examples of solutions to wafer processing problems using diamond tools.

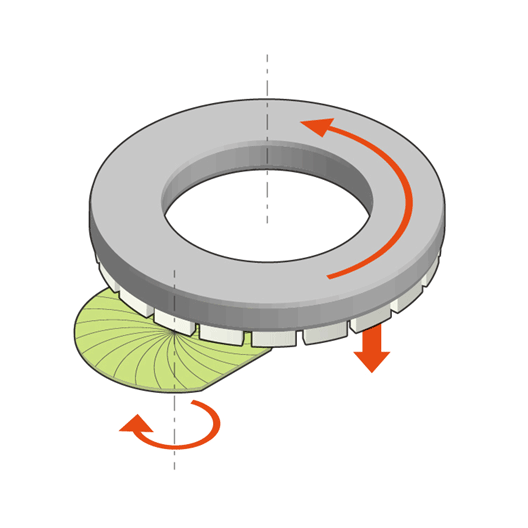

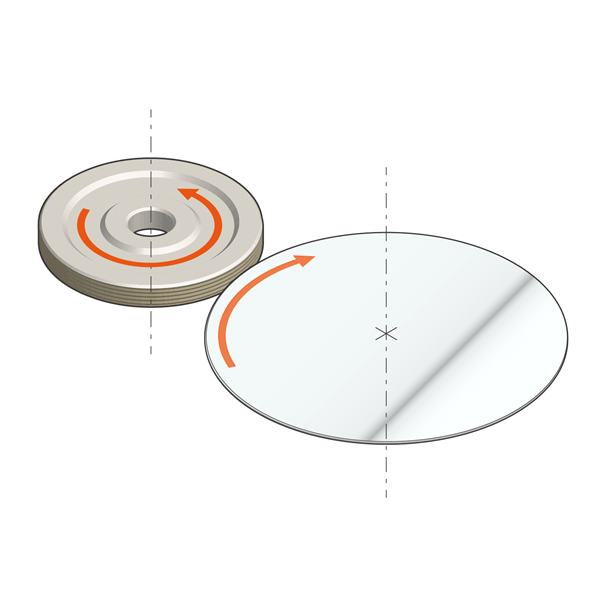

Problem-solving in surface grinding of SiC wafers

SiC is known as a difficult-to-machine material, causes severe wear of diamond wheels during surface grinding, resulting in increased processing time per unit.

Tokyo Diamond Tools Mfg. has developed a porous vitrified bond wheel with both grindability and wear resistance through proprietary abrasive structure control. The number of wafers that can be processed per wheel has been increased, reducing processing costs.

Problem-solving in edge grinding of compound wafers

In the edge grinding of compound wafers, which are used as substrates for power devices, challenges such as wafer chipping often occur, lowering yields and increasing processing costs.

Tokyo Diamond Tools Mfg. has developed a metal bonded edge grinding wheels that optimize the cutting performance on a per-grit basis with optimized sharpness for each abrasive cutting edge. This innovation reduces chipping in the grinding wheels and extends wheel life.

Problem-solving in processing sapphire wafers

For sapphire wafers used in LED devices, reducing costs by extending the life of grinding wheels was a challenge.

Tokyo Diamond Tools Mfg. has addressed this challenge by optimizing the combination of abrasive specifications and bond hardness, to solve the problems of metal bonding, such as "glazing” and “clogging". The optimization has resulted in an extended lifespan for grinding wheels.

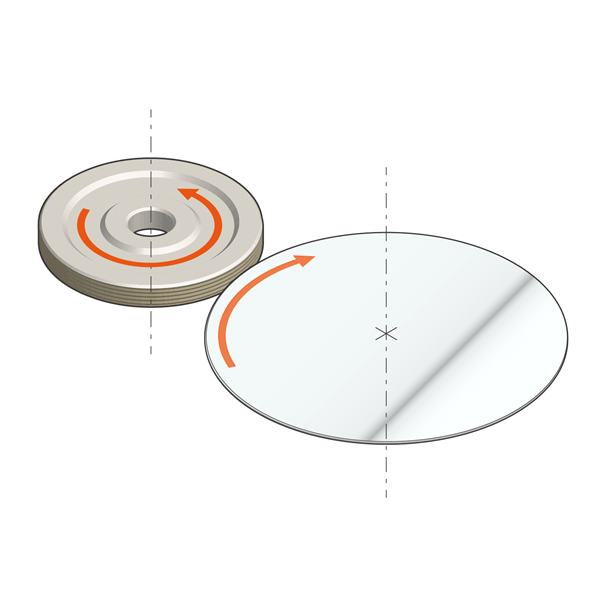

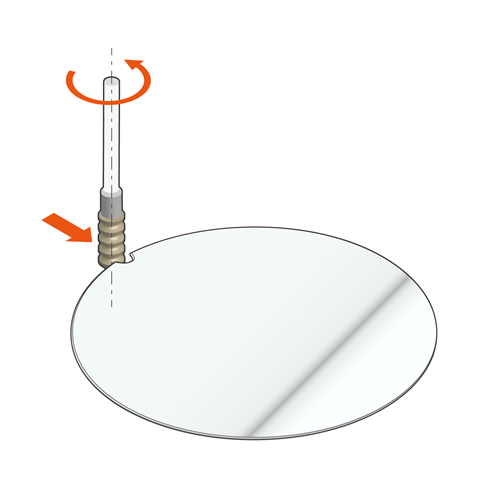

Problem-solving related in notch grinding of silicon wafers

In the notch grinding of silicon wafers, the increasing use of fine-grit abrasives posed a challenge in achieving extended tool lifespan. Tokyo Diamond Tools Mfg. addressed this challenge by improving the specification with high cutting-edge strength of the abrasive and bond strength. The adoption of original dressing technology contributed to a longer lifespan.

Please feel free to contact us on the challenges of wafer processing tools technologies

Tokyo Diamond Tools Mfg. has experience of improving efficiency and reducing the cost in wafer processing in the semiconductor industry, as demonstrated in the case studies presented here. We offer a wide range of grinding wheels customized to the material, processing requirements, and objectives. Whether you need a single wheel or a custom design, we are here to assist you.

If you have any concerns or questions regarding the selection or customization of diamond tools for wafer processing, do not hesitate to contact Tokyo Diamond Tools Mfg.