What is Lens Processing? Types of Lenses and Examples of Diamond Tool Applications

Lens processing refers to a series of cutting, grinding, and polishing operations in lens manufacturing. With the increasing pixel density of digital camera image sensors (CMOS) and growing demand for lenses for smart devices, the required performance of lenses continues to improve, and the processing technology has become more advanced. This column introduces examples of how diamond tools, which have been increasingly in demand in recent years, are used in lens processing.

Types of Lenses and Processing Methods

Lenses used in consumer products and industrial components are broadly classified into 'glass lenses' and 'plastic (resin) lenses'. They are selected according to their application, required quality, and cost considerations.

Glass Lenses

Glass lenses are made by cutting and shaping ingots of materials such as synthetic quartz. Before the development of high-transmittance resins, glass lenses were the standard type of lenses.

They are widely used across industries due to their high strength, heat resistance, and environmental durability. In recent years, the demand has diversified to include ultra-small lenses under 1 mm in diameter for endoscopes, large-diameter lenses for aerospace applications, and aspherical lenses that correct spherical aberrations and distortions.

The processing steps for glass lenses are generally divided into 'rough cutting,' 'polishing,' and 'centering.' Surface roughness and eccentricity greatly affect lens performance. Moreover, glasses with high light transmittance tend to be sensitive to heat and shock, requiring highly advanced processing techniques.

Plastic (Resin) Lenses

Plastic lenses were developed through advances in high-transmittance and high-refractive-index resins, along with improvements in injection molding technology. A familiar example is the contact lens.

In recent years, the demand for camera lenses for electronic devices such as smartphones has increased, leading to mass production of various types of plastic lenses. In some cases, they are also used as intraocular lenses for medical applications made of biocompatible resins, expanding their range of uses.

Since plastic lenses are molded using dies, they offer high shape flexibility and are well suited for mass production. Although many of these products do not require extremely high precision compared to glass lenses, the mold machining itself requires advanced processing technology.

Examples of Diamond Tool Applications

Lens processing requires a high level of technical expertise, and various processes make use of Tokyo Diamond Tools Mfg. Co., Ltd.’s diamond tools. Diamond tools are grinding wheels and cutting tools that use diamond particles as cutting edges. Leveraging diamond’s property as the hardest material on earth, they are used for processing glass lenses, plastic lenses, and molds that are difficult to machine with conventional tools.

- Related Column| What is diamond wheel ?

Applications for Glass Lenses

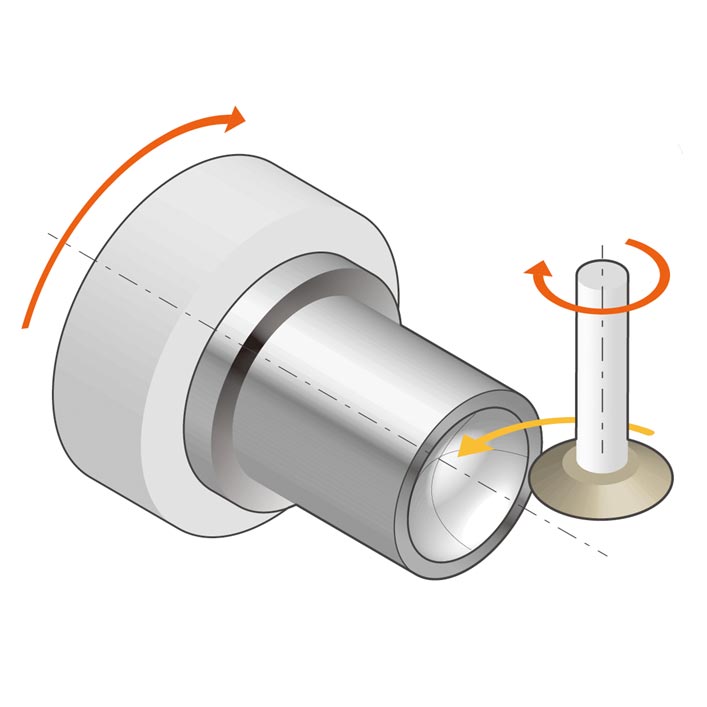

Centering of Glass Lenses

Centering is a process that removes eccentricity (misalignment of the optical axis) by grinding the lens periphery after polishing. Aspherical lenses and lenses for semiconductor exposure equipment require extremely high accuracy, within approximately ±0.005 mm. For this, optical lens centering diamond wheels are used.

Tokyo Diamond Tools Mfg. Co., Ltd. offers diamond wheels that minimize edge chipping and cracks, and can suppress lens burning even when processing steeply curved profiles.

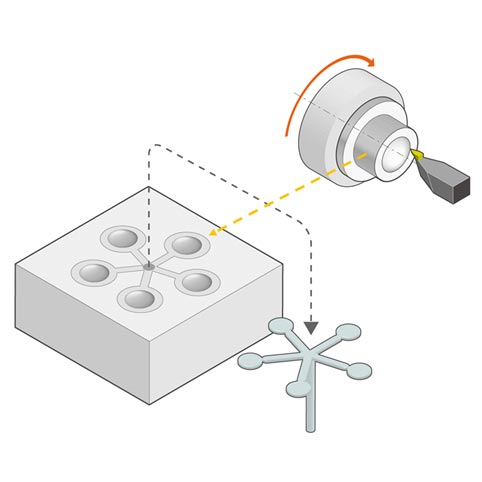

Processing of Glass Lens Molds

Binderless cemented carbide, used for molds forming aspherical glass lenses, features hardness and strength surpassing conventional cemented carbides. This has made efficient machining difficult with standard tools. To overcome this, diamond-mounted wheels are used.

Tokyo Diamond Tools Mfg. Co., Ltd. manufactures small-diameter mounted wheels customized for various mold types, including inclined-axis grinding, free-form surface grinding, and sleeve mold machining.

Applications for Plastic (Resin) Lenses

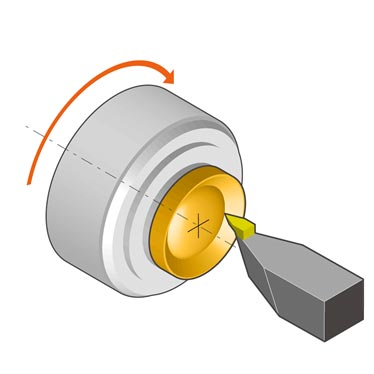

Processing of Plastic Lens Molds

Plastic lenses for smart devices are becoming larger and wider in angle, and the required accuracy for their molds is also increasing year by year. Nickel, commonly used for plastic molds, is a difficult-to-machine material, but single-crystal diamond bites are used for this purpose.

Tokyo Diamond Tools Mfg. Co., Ltd.’s single-crystal diamond bites have high edge contour accuracy and nearly scratch-free rake and flank surfaces, enabling highly precise mold machining.

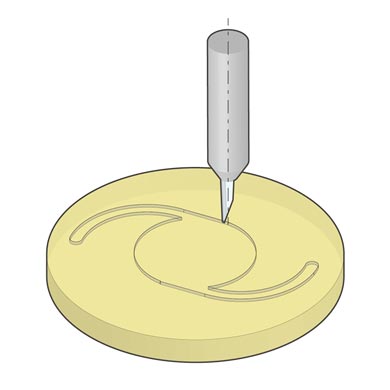

Processing of Plastic Lenses

High-quality and high-transparency plastic lenses are sometimes produced by direct cutting. For precision concave surface machining of plastic lenses, tool geometry must be carefully designed to prevent interference between the tool and the workpiece. In these processes, single-crystal diamond bites are used.

Tokyo Diamond Tools Mfg. Co., Ltd. has extensive know-how in designing and manufacturing cutting tools with geometries that avoid interference between the cutting edge and the workpiece.

Processing of Intraocular Lenses

With the aging population, demand for intraocular lenses used in cataract surgery has been increasing. High-quality intraocular lenses are manufactured through precision cutting, and single-crystal diamond end mills are used in this process.

Tokyo Diamond Tools Mfg. Co., Ltd.’s single-crystal diamond end mills provide sharp cutting edges that achieve low surface roughness, enabling high-precision machining with superior transparency in fewer steps.

Summary: Lens Processing and Diamond Tools

Tokyo Diamond Tools Mfg. Co., Ltd. offers a wide range of diamond tools for both glass and plastic lens processing, including the examples introduced in this column. If you are facing challenges in lens grinding or tool selection, please feel free to contact Tokyo Diamond Tools Mfg. Co., Ltd. for assistance.