Diamond mounted wheels for glass lens mold machining

Diamond mounted V-face wheels are tools mainly used for aspherical surface machining of glass lens molds.

For plastic lens molds, nickel is machined with an ultra-precise single-crystal diamond cutting tool, while ultra-fine binderless cemented carbide is used for glass lens molds. In addition, demand for SiC molds has been increasing recently.

For the machining of such binderless cemented carbide and SiC lens molds, grinding with a diamond wheel with shaft is used because cutting with a single-crystal diamond cutting tool is unsuitable and inefficient.

We have extensive experience with single-crystal diamond cutting tools for plastic lens molds, and also offer various specifications of diamond mounted wheels for glass lens mold machining.

In addition to V-face shaft wheels, we also offer cylindrical small-diameter shaft wheels for diagonal grinding, free-form grinding, dressing, and sleeve mold machining.

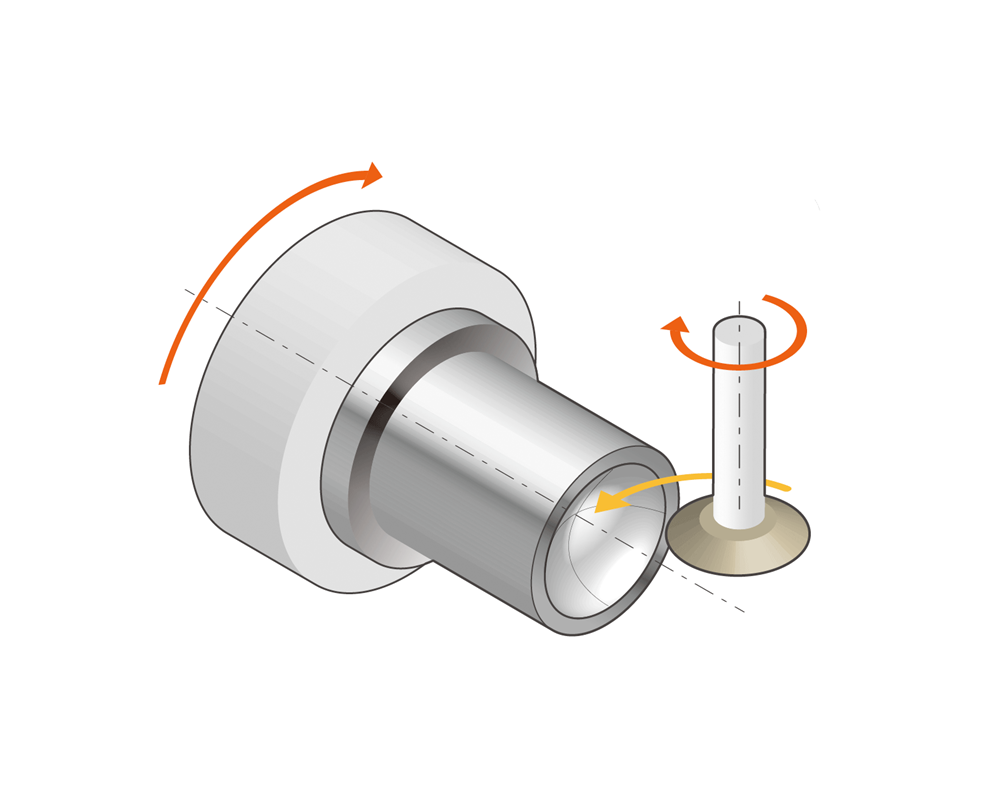

Image of grinding process for glass lens molding die

Typical Specifications of Mounted Wheels for Glass Lens Mold Processing

[Diamond mounted V-face wheel] *Typical specification

Outer diameter: 16D-70D

Angle: 30°-90°

Shaft diameter: φ6, φ8, φ10

Shaft material: Cemented carbide

Grain size: #325-#3000

Bond: Resin bond

[Diamond-mounted cylindrical shaped wheel] *Typical specification

Outer diameter: 3D-15D

Shaft diameter: φ6, φ10

Shaft material: Cemented carbide

Grain size: #200-#5000

Bond: Resin bond and vitrified bond

- Industories

- Work materials

- Processing methods