High quality machining of transparent resins such as contact lenses is achieved efficiently.

[Issues in cutting resin]

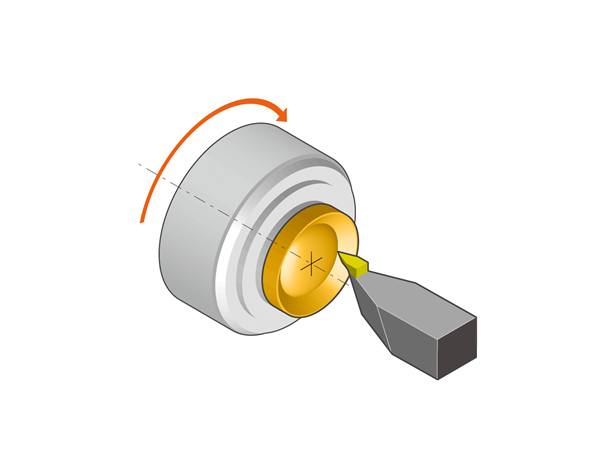

The cutting of resin, the material used for contact lenses, requires very high quality machining to achieve sufficient transparency. In addition, when machining small concave curved surfaces, the shape of the cutting edge must be designed so that nothing other than the tip of the cutting edge interferes with the work material.[Solution with monocrystalline diamond cutting tools]

Mono-crystal diamond cutting tools have very sharp cutting edges compared to cemented carbide cutting tools, etc., and can keep machining surface roughness small, enabling transparent resin forming in just one process. In addition, Tokyo Diamond Tools Mfg. Co., Ltd. has accumulated know-how in designing and manufacturing cutting tools with shapes such that nothing other than the tip of the cutting edge interferes with work materials in the machining of small concave curved surfaces, and we can respond to a wide range of customer requirements.

Example shape of cutting edge for small concave surface

Optimal cutting tool for machining of resin

Mono-crystal diamond cutting tool

Please feel free to consult us for details.