Ceramics Processing in the Semiconductor Industry: Case Studies of Solutions Using Diamond Wheels

Diamond wheels are grinding and cutting tools that use diamond particles as the cutting edges. In the semiconductor manufacturing process, they are essential for processing hard and brittle materials such as wafers. As demand for semiconductor equipment continues to rise, the need for precision machining of ceramics used in semiconductor equipment components has also increased dramatically. This column summarizes examples of how diamond wheels help solve challenges in ceramics machining.

Challenges in Ceramics Machining for the Semiconductor Industry

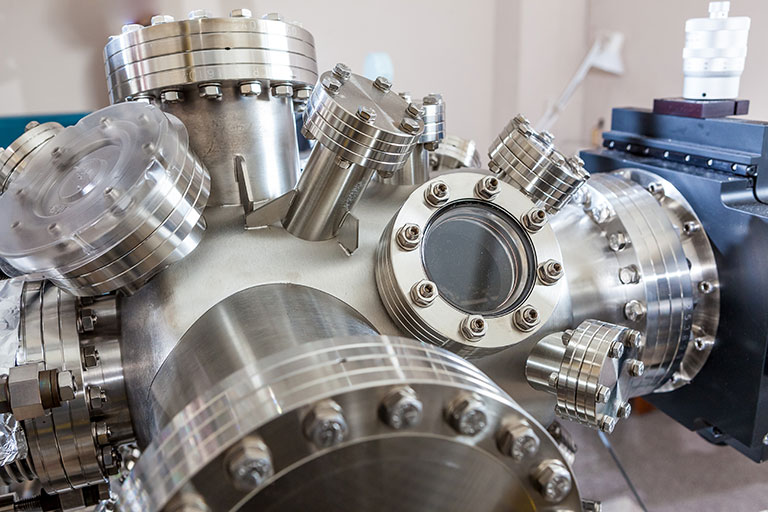

Ceramics are inorganic compounds characterized by excellent properties such as wear resistance, heat resistance, lubricity, and insulation. Among them, fine ceramics (advanced ceramics) play an indispensable role in semiconductor manufacturing equipment due to their superior characteristics.

Examples of ceramic applications in semiconductor manufacturing equipment include:

| Component Example | Ceramic Property | |

|---|---|---|

| Various Equipment Components | Wear resistance | Prevents particle generation and contamination |

| Electrostatic Chuck | Thermal conductivity | Provides efficient heat transfer to wafers |

| Focus Ring | Plasma resistance | Enables use inside plasma chambers |

| Wafer Boat | Heat resistance | Allows installation inside high-temperature chambers |

About Fine Ceramics:

Fine ceramics possess unique characteristics unattainable with metals or plastics, such as superior corrosion and heat resistance. Their applications span from information and communication components to optical devices and everyday materials, making them essential across various industries.

Source: Fine ceramics manufacturing industry|Ministry of Health, Labour and Welfare

In semiconductor manufacturing, ceramics like SiC and aluminum nitride are known as difficult-to-machine materials due to their hardness and brittleness. The challenge for parts manufacturers is achieving efficient processing of these ceramics. This is where diamond wheels excel, offering superior hardness and durability for high-efficiency machining while maintaining tool life and precision.

Case Studies: Solving Challenges in Ceramics Machining with Diamond Tools

Tokyo Diamond Tools Mfg. Co., Ltd. offers a comprehensive lineup of diamond tools designed to meet various machining needs for ceramics. Below are examples of how our diamond tools have solved specific challenges in ceramics machining.

Solving Groove Machining Challenges for SiC

SiC groove machining using multiple metal bond or electroplated wheels tends to cause vibration and chipping due to grinding load. To address this, Tokyo Diamond developed a composite resin-metal bond wheel that significantly reduces chipping while achieving excellent form retention, grinding sustainability, and long tool life.

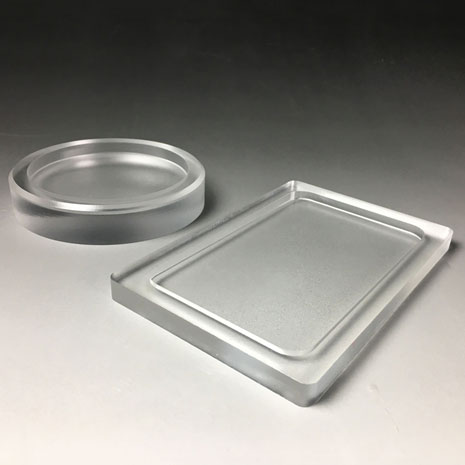

Solving Counterbore Machining Challenges for Aluminum Nitride

Stable grinding performance is essential for machining ceramics such as aluminum nitride. Tokyo Diamond developed a bond that enhances sharpness even at low current values, achieving stable grinding with reduced grinding resistance compared to conventional bonds.

Achieving High-Efficiency Machining for Ceramics

For ceramics machining, tools that maintain sharpness while enabling high throughput in short cycle times are in demand. Tokyo Diamond developed a metal bond with superior self-dressing properties, combining the sharpness of resin bonds with the wear resistance of metal bonds for high-efficiency ceramics machining.

Supporting Ultrasonic-Assisted Machining for Ceramics

More companies are adopting ultrasonic-assisted grinding for high-efficiency machining of ceramics such as SiC. Tokyo Diamond developed ultrasonic-assisted mounted wheels capable of effectively transmitting resonant vibration to the workpiece. By optimizing bond specifications, both sharpness and wear resistance are achieved, enabling efficient and stable machining of ceramics.

Consult with Us About Your Ceramics Machining Challenges

Tokyo Diamond Tools Mfg. Co., Ltd. has extensive experience providing high-efficiency machining solutions for ceramics used in semiconductor manufacturing equipment. We propose optimal grinding wheels tailored to each machining application and objective, and we design and produce each wheel to order. If you face difficulties selecting or customizing diamond tools for ceramics machining, please feel free to contact Tokyo Diamond Tools Mfg. Co., Ltd. for consultation.