"Copper-free" metal bond wheel with spindle for semiconductor manufacturing equipment components

This is a copper-free metal bond wheel with spindle that limits the use of copper and steel in the bond.

The "copper free" wheel uses a unique bond formulation to achieve mechanical properties comparable to those of bronze-based bonds without the use of copper.

In machining tests, it has a grindability and lifespan comparable to that of bronze-based bonds.

The use of copper-free wheels prevents copper contamination of workpieces when machining jigs used in the preprocessing of semiconductors, which are particularly sensitive to copper contamination, and reduces the need for cleaning and removal processes in subsequent processes.

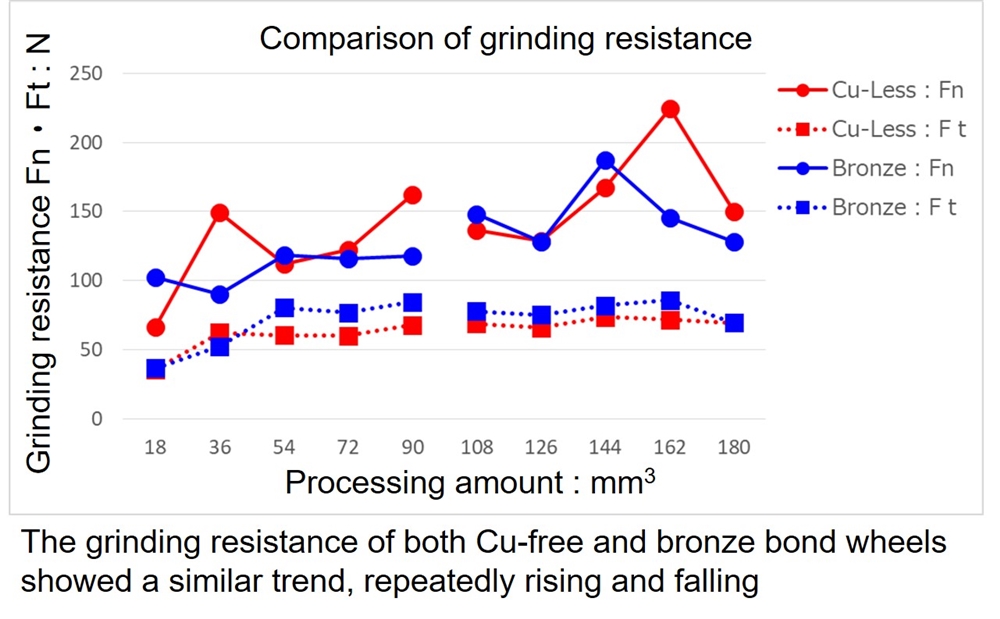

Comparison of grinding resistance with conventional bronze-based bonds

Test Processing Conditions of Copper Free Metal Bond Wheel

[Test machining conditions]

Machine: Gliding center

Rotation speed: 3200 rpm

Feed rate: 200 mm/min

Depth of cut: 30 μm/pass

Coolant: Water soluble coolant

Workpiece: SiC ceramics

[Test wheel specifications]

Particle size: #50

Size: 30D-10T-5W-6Y-40L

[Applicable size and specifications of wheel with spindle】*For reference

■Wheel outer diameter: f50 or less

■Wheel T-dimension: 30T or less

■Wheel length: 100L or less

■Particle size: #50-

Bond for Mounted Wheels

Metal bond

- Industories

- Work materials

- Processing methods