【Solution Case】Improving Efficiency in Semiconductor Equipment Component Machining

As semiconductor devices become increasingly miniaturized and highly integrated, machining manufacturers face the dual challenge of achieving both high precision and productivity. In particular, during the machining of semiconductor equipment components, issues such as chipping and short tool life are frequently encountered. This column introduces common machining challenges in semiconductor equipment manufacturing and how these can be solved using diamond wheels from Tokyo Diamond Tools Mfg. Co., Ltd.

Challenges in Machining Hard and Brittle Materials

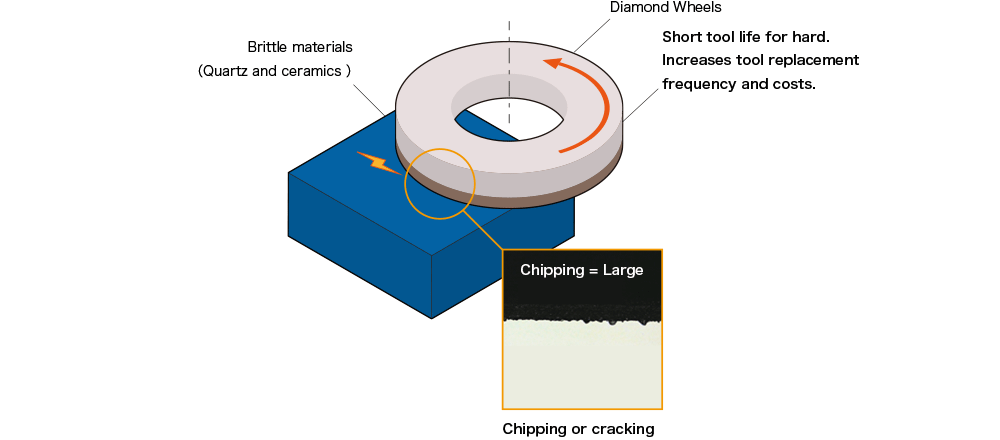

Components used in semiconductor manufacturing equipment often require heat resistance and insulation properties, which is why hard and brittle materials such as quartz and ceramics are commonly used. These materials are utilized in both front-end and back-end processes, and high-quality machining is indispensable.

However, machining hard and brittle materials is never simple. When machining efficiency is increased, the risk of edge chipping or thermal cracking also rises due to grinding loads. Additionally, these materials impose heavy loads on tools, resulting in shorter tool life, more frequent replacements, and higher setup and running costs.

Key Challenges:

- Increasing machining efficiency often causes chipping or cracking on workpieces.

- Short tool life for hard and brittle materials increases tool replacement frequency and costs.

Solutions Using Diamond Wheels

For hard and brittle materials, diamond wheels—tools that use diamond particles as cutting edges—are typically employed. Although diamond wheels offer excellent sharpness, they can also cause chipping or cracking during machining. To overcome these challenges, Tokyo Diamond Tools Mfg. Co., Ltd. developed advanced diamond wheels that combine sharp cutting performance with stability and durability.

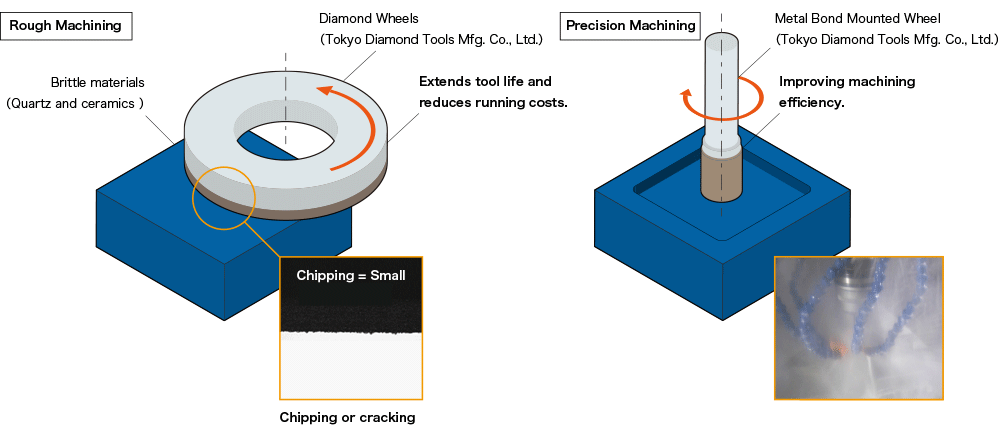

Our diamond wheels achieve outstanding sharpness through decades of expertise in abrasive grain and bond selection, as well as optimized slit design. They allow higher machining speeds while suppressing chipping, achieving both high precision and productivity. Furthermore, their long-lasting sharpness and extended tool life reduce dressing and replacement frequency, contributing to lower setup time and overall cost.

These diamond wheels are widely adopted in machining parts such as quartz glass components for etching equipment and electrostatic chucks for silicon wafer fixation.

Improvement Highlights:

- Suppresses chipping and cracking of hard and brittle materials while improving machining efficiency.

- Extends tool life and reduces running costs.

Recommended Tools for Semiconductor Equipment Component Machining

Ideal for Rough Machining

Diamond Pellet Wheel

A grinding wheel designed for large-area surface flattening using rotary surface grinders.

Arranged diamond pellets enhance the flow of grinding fluid to the contact area, reducing heat damage to both the workpiece and the wheel. Pellets are replaceable, allowing the base metal plate to be reused, which helps reduce wheel costs.

Ideal for Precision Machining

Metal Bond Mounted Wheel

A mounted grinding wheel suitable for machining centers and grinding centers.

The metal bond offers strong abrasive retention, maintaining excellent sharpness even on hard materials. With high thermal conductivity, it prevents heat accumulation at the grinding point, reducing thermal cracks in hard and brittle materials. Compared with electroplated tools, it provides significantly longer tool life and is ideal for processing hard ceramics such as SiC and aluminum nitride.

For Copper-Sensitive Components

Copper-Free Metal Bond Mounted Wheel

This wheel features a unique bond composition that eliminates copper while maintaining mechanical performance comparable to bronze bonds. It prevents copper contamination and reduces the need for post-process cleaning and removal. It is ideal for machining jigs and components used in front-end processes where copper contamination is undesirable.

Contact Us for Consultation

With the increasing miniaturization and performance of semiconductors, even minor chipping that was once acceptable is now considered a defect, leading to lower yields. Tokyo Diamond Tools Mfg. Co., Ltd. can propose optimal bond specifications tailored to machining conditions and materials. We also provide a variety of wheel shapes according to application needs—including small-diameter core-drill-type wheels with slit structures that improve chip evacuation.

Consultations from manufacturing sites worldwide are increasing every year. For yield improvement and stable quality, please feel free to contact us for customized solutions.