Longer life of beveling wheels for sapphire wafers

[Issues in machining of sapphire wafers]

In the global trend toward power saving, LEDs are becoming more and more popular, and there is a need to reduce the cost of sapphire wafers, which are the mainstream substrates for LEDs. One of the ways to reduce the machining cost of sapphire wafers is to extend the dressing interval of the wheel in the wafer beveling process and to extend the service life of the wheel.[Solution with metal bond wheel]

Tokyo Diamond Tools Mfg. Co., Ltd. has focused on the grain changing action that has been an issue with metal bonds for silicon wafer beveling. By optimizing the combination of the type of abrasive grains and the hardness of the bond, we have solved the problem of "dulling," in which the abrasive grains are defeated by the hard material, and "clogging," in which the grinding dust of the work material adheres to the abrasive surface by holding the abrasive grain persistently.

Optimal Grinding Tool for Sapphire Wafer Processing

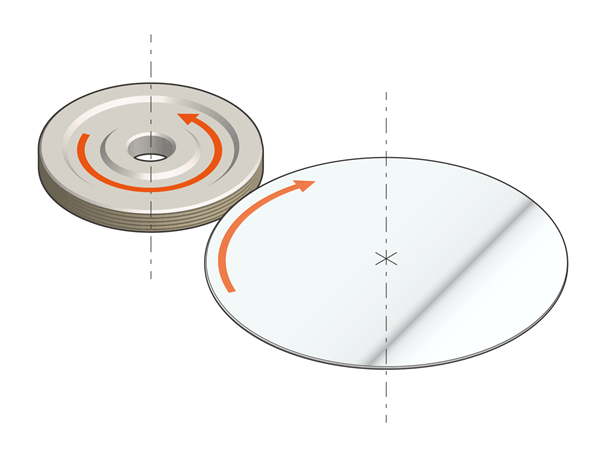

“MFX” Metal bond beveling wheel for sapphire wafer

[Possible production range]

Grain size : #400 - #3000 *Compound grain size is also available.

Outer diameter : Up to 202D

Internal diameter tolerance: H6

(Please consult with us for other tolerances.)

Dynamic balance: ≧0.1 g @Min.

Groove shape tolerance : ≧ 0.5 degrees

Number of grooves: Up to 10 grooves (more than 10 grooves are possible

depending on groove shape.)

■Optimized combination of abrasive grain and bond characteristics with the material properties of sapphire taken into account can significantly reduce dulling and clogging.

■Long life of the wheel is realized by appropriate bond tail formation during grinding, removal of chips, and effective coolant supply.

■During continuous machining of sapphire wafers diameter variation and linearity of orientation flat can be maintained in a stable manner and a life span about three times longer than that of a conventional wheel is realized.