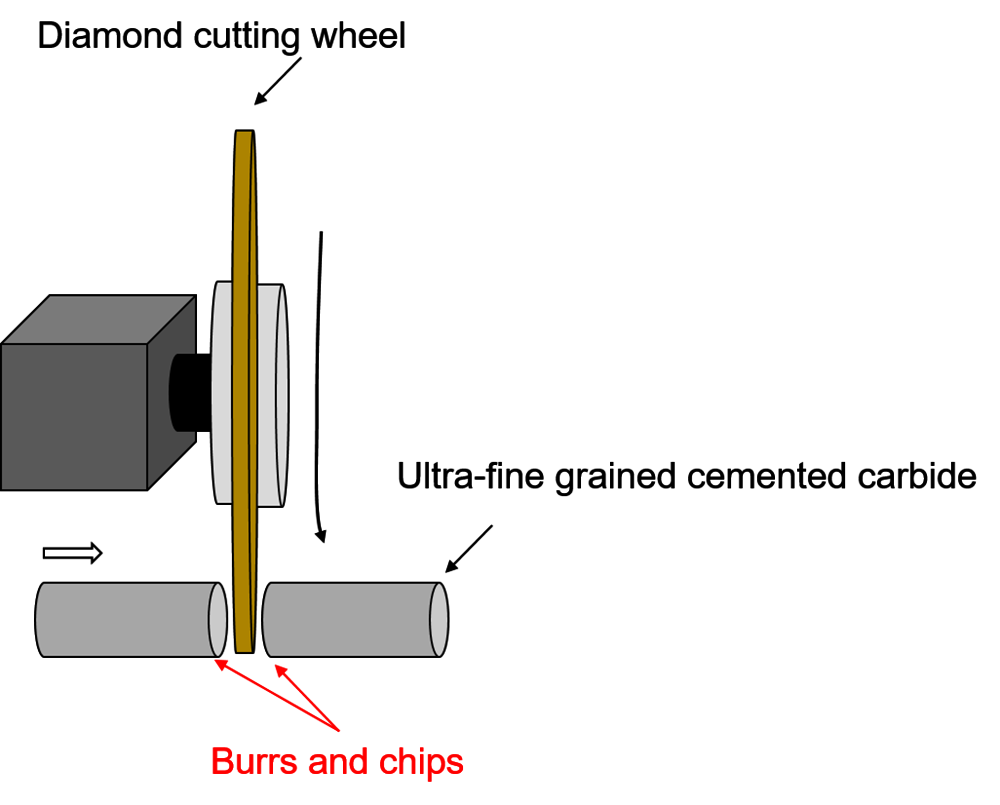

The cutting process for ultra-fine grained cemented carbide.

[Issues in machining ultrafine cemented carbides]

Ultra-fine grained cemented carbide is a material that is harder and less machinable than general cemented carbides.

In the round bar cutting process by ultrafine grained cemented carbides, burrs and chips are generated on the cut-off side of work pieces due to insufficient sharpness of the diamond cutting wheel.

In addition, frequent wheel replacement is necessary due to the short life of diamond wheels.

[Solution with resin + metal composite bond cutting wheel]

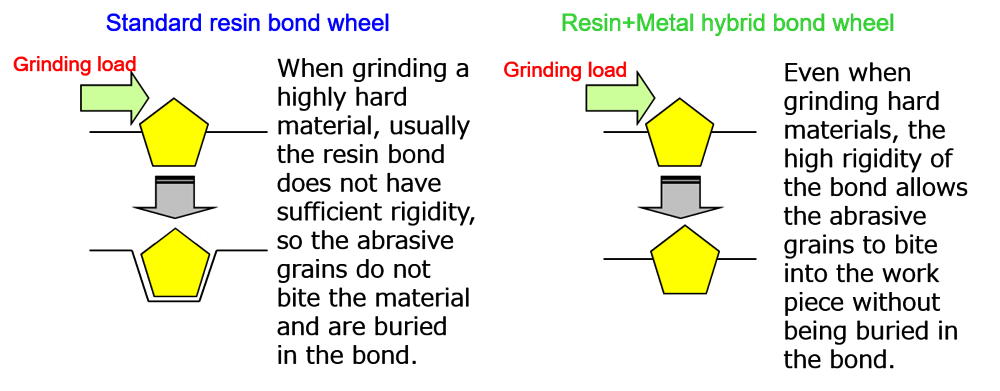

Cutting wheels are made with a composite bond of resin and metal, where metal powder and other materials are added to a resin-based bond.

As a result of high bond hardness, high strength, and low elasticity, the burial of abrasive grains is suppressed. Therefore, when cutting by ultra-fine grained cemented carbides, which are harder than general cemented carbides, excellent sharpness is demonstrated and the generation of burrs and chips is reduced.

The wheel life is long, i.e. about twice as long as that of a standard resin bond, due to the high hardness and strength of the bond.

Mechanism of resin + metal composite bond

Cutting Test Conditions of Ultrafine Cemented Carbide

Machine : General-purpose cutting machine (Heiwa Technica)

Workpiece :Ultra-fine grained cemented carbide

Work size :Round bar φ6

Wheel size : 205D-0.7T

Wheel spec. : Diamond abrasive size #170 / Bond type BDM

Result : 3900 cuts/piece

(1900 cuts/piece for wheels made by other manufacturers)

Approximately twice the life span of the product

Optimal grinding tools for cutting ultra-fine cemented carbides

Diamond cutting wheels

These wheels are used for cutting and grooving cemented carbide / tungsten carbide, cermet, ceramics, glass, ferrites, semiconductors, carbon, and other non-iron metal materials. They realize less bending and a higher quality cutting surface. A resin bond CBN wheel is provided for cutting neodymium magnets.