Product List

-

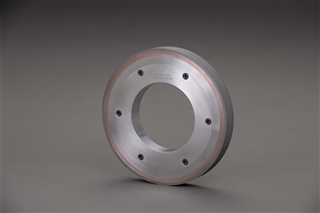

“DEX” diamond wheels for chamfering glass disks

These wheels are used to chamfer the inner diameter (ID) or outer diameter (OD) edge of glass disks. Due to the special electroplating used in this design, the roughness of chamfered surfaces are improved and chipping at the boundary area to the edge surface is minimized. Wheels using micron size abrasive grain are available.

These wheels are used to chamfer the inner diameter (ID) or outer diameter (OD) edge of glass disks. Due to the special electroplating used in this design, the roughness of chamfered surfaces are improved and chipping at the boundary area to the edge surface is minimized. Wheels using micron size abrasive grain are available. -

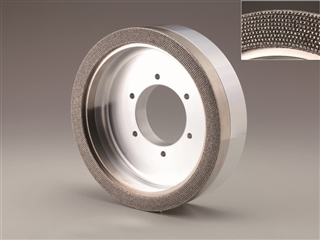

“DEX Duo” Electroplated Wheel for Hard Brittle Materials

■Realizing persistence of the grinding performance of the diamond abrasive grains and longer tool life.

■Realizing persistence of the grinding performance of the diamond abrasive grains and longer tool life.

■The long tool life stabilizes the processing quality. -

“DEX” diamond wheels for forming difficult-to-cut materials

These wheels are designed for high shape precision forming of, for example, motor cores. Wheels of the most appropriate specifications are available for not only magnetic materials such as neodymium-iron, but also for ferrites, ceramics and glass.

These wheels are designed for high shape precision forming of, for example, motor cores. Wheels of the most appropriate specifications are available for not only magnetic materials such as neodymium-iron, but also for ferrites, ceramics and glass. -

“DEX” diamond wheel for high-efficiency milling of difficult-to-cut materials

This wheel enables deep milling of difficult-to-cut composite fiber materials such as brake linings, architectural ceramic materials, secondary products of cement, carbon, FRP, and thermoset resins. The amount of ground material removed per unit time is relatively large, which realizes highly efficient grinding. By controlling the contact area between the material being ground and the wheel, this design reduces grinding noise, suppresses additional electric current in the main spindle, and contributes to energy saving.

This wheel enables deep milling of difficult-to-cut composite fiber materials such as brake linings, architectural ceramic materials, secondary products of cement, carbon, FRP, and thermoset resins. The amount of ground material removed per unit time is relatively large, which realizes highly efficient grinding. By controlling the contact area between the material being ground and the wheel, this design reduces grinding noise, suppresses additional electric current in the main spindle, and contributes to energy saving. -

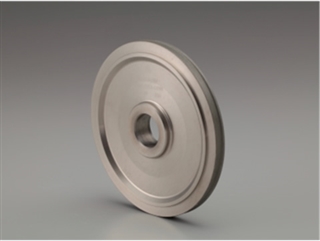

“DEX” diamond wheel for optical lens centering

This wheel is used for axis alignment (optical lens centering) of aspherical lenses or steppers used in high-grade cameras or endoscopes, which usually require high-precision grinding. When used, pre-conditioning grinding is not necessary and lens manufacturing with less damage on the lens edge starts from the beginning of processing work. The wheel can also suppress lens coloring, even when a steep rise shape is used.

This wheel is used for axis alignment (optical lens centering) of aspherical lenses or steppers used in high-grade cameras or endoscopes, which usually require high-precision grinding. When used, pre-conditioning grinding is not necessary and lens manufacturing with less damage on the lens edge starts from the beginning of processing work. The wheel can also suppress lens coloring, even when a steep rise shape is used. -

“DTFC”” Mounted Wheel/Cutting Wheel for Cutting/Grinding CFRP “

■Significantly suppresses burr and peel ply (delamination) and realizes high-quality and high-precision machining.

■Significantly suppresses burr and peel ply (delamination) and realizes high-quality and high-precision machining.

■Reduces mass production cost by removing manual finishing process, realizing long product life, and reusing by re-electroplate.

■Reduction of manual finishing process can suppress precision variation and is effective for finishing junctions which require high precision. -

“Metalist” CBN Metal Bond Wheel for Iron Material

By using the metal bond having significantly higher heat conduction than a vitrified bond, the influence of heat on the working surface is minimized.

By using the metal bond having significantly higher heat conduction than a vitrified bond, the influence of heat on the working surface is minimized.

■ The product not only maintains cutting performance and realizes long tool life, but also suppresses burning of work materials.

■ Since it can suppress heat stress on work materials more than conventional abrasive wheels, reduction of the fatigue-resistant strength of the work can be suppressed.

■ Little damage on abrasive grains and appropriate spontaneous blade generation can realize long dress intervals and reduce down time.

[Target materials for CBN metal bond wheels]

- HSS (High-Speed Steel)

- Hardened Steel (carbon steel, die steel) -

CBN wheels for grinding iron materials

These wheels realize high-precision grinding of iron materials used for automobile parts and the like. They provide the advantages of high performance and stable quality. CBN wheels with an axis are also available.

These wheels realize high-precision grinding of iron materials used for automobile parts and the like. They provide the advantages of high performance and stable quality. CBN wheels with an axis are also available. -

“CITIUS” diamond wheels for heavy grinding of carbide tools

These wheels demonstrate their distinguished performance for deep-gutter flute grinding of cemented carbide / tungsten carbide tools. Compared to conventional resin bond wheels, they reduce machining time and abrasion. They also achieve stable cutting performance, high-precision, and high-quality surface roughness, and reduce the generation of chips. "BI30" and "MB" series resin bond wheels are also available depending on the materials to be ground and on usage.

These wheels demonstrate their distinguished performance for deep-gutter flute grinding of cemented carbide / tungsten carbide tools. Compared to conventional resin bond wheels, they reduce machining time and abrasion. They also achieve stable cutting performance, high-precision, and high-quality surface roughness, and reduce the generation of chips. "BI30" and "MB" series resin bond wheels are also available depending on the materials to be ground and on usage. -

“high-RESPONSE” diamond wheels for grinding PCD/PCBN tools

These wheels are used for grinding PCD and PCBN tools, which have higher hardness, higher strength and higher abrasion resistance than carbide tools. Two (non-porous and porous) "high-RESPONSE" bond types are available to meet customer needs for higher precision and higher efficiency.

These wheels are used for grinding PCD and PCBN tools, which have higher hardness, higher strength and higher abrasion resistance than carbide tools. Two (non-porous and porous) "high-RESPONSE" bond types are available to meet customer needs for higher precision and higher efficiency.